The finite element method (FEM) is a numerical technique for finding approximate solutions to boundary value problems for partial differential equations. It is also referred to as finite element analysis (FEA). FEM subdivides a large problem into smaller, simpler, parts, called finite elements. The simple equations that model these finite elements are then assembled into a larger system of equations that models the entire problem. It’s a technique to evaluate the stresses & other engineering terms to decide the failure of the components. Designs can be evaluated and refined using computer simulations rather than physical prototype testing, saving money and time. Finite Element Analysis outsourcing and consulting services. At SysCAD Techno Solutions, we believe that your success depends on technical excellence as well as on competitive product design solutions and time to market. Our team consists of specialized analytical consultants that have years of industry expertise in High End Engineering. Engineering projects require quick turnaround, manufacturing information, exposure to standards and cost sensitivity, all in one go. SysCAD Techno Solutions offers a single window for all Engineering product design requirements by in best in class solutions.

At SysCAD Techno Solutions, our Finite Element Analysis (FEA) services play a crucial role in ensuring the safety, reliability, and optimal performance of mechanical designs. By leveraging advanced simulation techniques, we accurately analyze complex engineering problems, enabling us to offer innovative solutions that enhance product design and prevent potential failures.

Structural Analysis: Ensuring Safety and Optimizing Designs

Importance of Structural Analysis: Structural analysis is essential for identifying potential weaknesses in a design and ensuring its safety under various loading conditions. At SysCAD Techno Solutions, we conduct comprehensive structural analysis to validate and optimize designs, minimizing the risk of structural failures.

Preventing Failures and Optimization: Our structural analysis expertise has saved numerous projects from costly failures. In one such instance, we identified stress concentration areas in a critical component of a bridge design and proposed design modifications that significantly increased its lifespan while adhering to safety standards.

Thermal Analysis: Enhancing Thermal Management and Performance

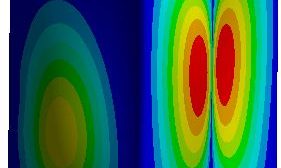

Contributing to Thermal Management: Thermal analysis is a critical aspect of modern product design, especially for components exposed to varying temperatures. By simulating heat transfer and temperature distribution, our thermal analysis ensures efficient thermal management, leading to better product performance and reliability.

Efficient Cooling and Heating Solutions: In a recent project involving electronic components, our thermal analysis led to the optimization of heat sink design, improving heat dissipation and preventing overheating. This resulted in increased product reliability and extended component lifespan.

Vibration Analysis: Enhancing Product Durability and Performance

Significance of Vibration Analysis: Vibration analysis is crucial in understanding a product’s response to dynamic forces and vibrations. By predicting potential vibration-related issues, we can optimize designs to improve durability and performance.

Mitigating Vibration-Related Issues: In an automotive project, our vibration analysis identified resonance frequencies in a vehicle’s suspension system, leading to design modifications that significantly reduced road-induced vibrations and improved ride comfort.

Contact Analysis: Ensuring Mechanism Reliability

Ensuring Mechanism Reliability: Contact analysis is essential for mechanisms involving moving parts that come into contact. Our simulations ensure that contact forces, pressures, and friction between components are within safe limits, ensuring reliable performance.

Optimizing Contact Performance: In a machinery project, our contact analysis of gear mechanisms allowed us to optimize gear profiles, reducing wear and improving the overall efficiency of the system.

Dynamic Analysis: Understanding Product Behavior Under Varying Conditions

Enhancing Product Understanding: Dynamic analysis helps us comprehend how products behave under varying operational conditions. This insight is invaluable for optimizing designs to withstand dynamic loads and prevent catastrophic failures.

Preventing Dynamic Failures: In a construction project, dynamic analysis revealed potential resonance issues in a bridge design due to wind forces. Our recommendations for damper implementation ensured the bridge’s stability and safety under varying weather conditions.

We offer the following Engineering Analysis:

- Static Structural Analysis:- Utilized to assess the effects of applied loads on a structure, this analysis predicts its response without considering the element of time. It helps identify potential deformation, stresses, and failure points, enabling precise structural design adjustments.

- Nonlinear Analysis (Material, Contact and Geometric Nonlinearity):- For complex scenarios involving material nonlinearities (like plastic deformation), contact nonlinearities (such as friction), or geometric nonlinearities (significant deformations), this analysis accounts for these intricacies, offering a more realistic understanding of the system’s behavior.

- Modal, Natural Frequency Analysis:- By studying a system’s natural modes of vibration and their corresponding frequencies, this analysis unveils critical structural resonances. Engineers use this information to design structures that avoid harmful vibrations and ensure stability.

- Harmonic Analysis, Rotodynamic Analysis:- In cases where cyclic loading or rotating machinery is involved, harmonic analysis studies the system’s response to sinusoidal excitations. Rotodynamic analysis, a subset, focuses on rotating equipment’s dynamics and helps prevent instabilities and failures.

- Frequency Response Analysis, Response Spectrum Analysis:- Frequency response analysis evaluates a structure’s response to varying frequencies of external loads, unveiling resonance points. Response spectrum analysis, often used for seismic evaluations, examines how a structure would behave during specific ground motions, offering insights into potential vulnerabilities.

- Random Vibration Analysis, Probabilistic Analysis:- For systems subject to unpredictable vibrations or loads, random vibration analysis evaluates their response to stochastic inputs. Probabilistic analysis assesses the impact of uncertainties in material properties, loads, and geometry, enhancing reliability predictions.

- Full Transient Dynamic Analysis:- This dynamic analysis accounts for time-dependent loads and their effects on a structure over time. It’s crucial for understanding how transient events, like impacts or sudden loads, influence the system’s behavior.

- Impact Analysis, Drop Analysis:- Focusing on the effects of sudden impacts, drop analysis evaluates a structure’s response to forces generated during a drop or impact event. This is essential for designing products that can withstand shocks without failure.

- Explicit Dynamics:- When rapid changes, large deformations, or dynamic events occur, explicit dynamics analysis simulates highly nonlinear behaviors. It’s used for scenarios like crash simulations and high-speed impacts.

- Fatigue Analysis:- Assessing the accumulation of damage over time due to cyclic loading, fatigue analysis ensures structures withstand repeated stresses without failure. It’s vital for estimating a component’s service life.

- Thermal Analysis:- Thermal analysis predicts temperature distributions within a structure due to heat sources or environmental conditions. This helps prevent thermal stresses and distortion.

- Thermo-Mechanical Analysis:- Combining thermal and mechanical considerations, thermo-mechanical analysis accounts for how temperature changes influence a structure’s mechanical behavior, critical for designing components subjected to varying temperatures.

- FSI (Fluid Structure Interactions):- FSI analysis examines how fluid flow affects nearby structures and vice versa. It’s used for scenarios like assessing the interaction between wind and buildings.

- Creep Analysis:- In situations involving prolonged exposure to high temperatures and constant loads, creep analysis studies how materials progressively deform over time.

- Manufacturing Tools and Device Analysis, Machining Fixture Analysis:- These analyses evaluate the structural integrity of tools, devices, and fixtures used in manufacturing processes, ensuring their reliability and safety during operation.

- Pressure Vessel Analysis, Heat Exchanger Analysis and Process Equipment Analysis:- These analyses ensure pressure vessels, heat exchangers, and other process equipment meet safety standards, considering factors like pressure, temperature, and material properties.

- Weld Joint, Bolt Joint Evaluation and Analysis:- These analyses assess the structural integrity of welded and bolted joints, vital for reliable connections in various industries.

- Seismic and Wind Loading Analysis:- These analyses evaluate a structure’s response to seismic and wind loads, essential for designing buildings and structures in earthquake- and wind-prone areas.

- Impact and Drop Test Analysis: Simulates structural response to sudden impact or drop loads, ensuring product durability and safety under accidental or handling-related forces.

We also provide Packaging Simulations for Stacking, Drop & Transport loading conditions so that during handling the product will not be damaged. We have own standards for this Simulations.

These specialized analyses empower us to solve intricate engineering problems across various industries. From product design enhancements to ensuring equipment reliability, our FEA analysis services cater to your unique needs.

For reliable FEA services and innovative solutions that enhance your product designs, contact us today! Our team of skilled engineers is committed to delivering excellence and ensuring the success of your projects.